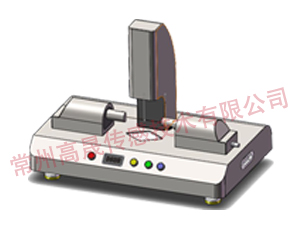

The Product Description

Steel wire automatic measuring gauge is a vision-based measuring instrument developed by Changzhou Golden Sensing Technology Co., Ltd. It achieves a high-precision automatic measurement of the wave height, wavelength and other parameters of steel wire with special deformation (structure line). At the same time, it is equipped with the wire tension measurement and display. With the original software platform on PC, the system supports the image processing results display, the parametric curve drawing and analysis, data offline storage, and ERP connection, etc. In addition, since the operating authority level security is set in the system, the issues can be tracked by reading the information records of the operator. Moreover, the system can be customized on the basis of customer's request. The instrument has been widely used in the area of off-line sampling and measurement, and it has been applied in Baosteel and some other famous enterprises.

Features

1. Automatic: Steel wire measuring gauge can implement automatic 360° measurements, analyze the measured data, derive the results, draw and display the data curve within a period of 30s.

2. High precision: Machine vision inspection mode is applied. With image process algorithm, the resolution can reach 0.1 um and repeatability is less than ± 3 um.

3. Integrated design: With the integrated design, the degree of protection has been improved since only external power supply cable, communication cable and USB cable are required. In addition, the system is convenient to install and operate.

4. Optimized software function: Image processing results can be displayed in real time. Parameter curve can be drawn and analyzed. The obtained data can be stored offline, and ERP connection can be extended.

5. Accurate measurement and adjustment to tension: The tension can be adjusted flexibly and accurately, and the value can be accurately displayed with the inner measuring system in real time.